- antenna receiving surface

- Auto Parts-Exhaust Pipe Parts

- Chemical equipment accessories-pressure port

- Chemical equipment accessories-wind blade

- Flowerpot-pure copper flowerpot with hole

- food machinery and equipment-funnel

- food machinery-feeding tray

- Living room lamp panel

- Snare drum copper shell

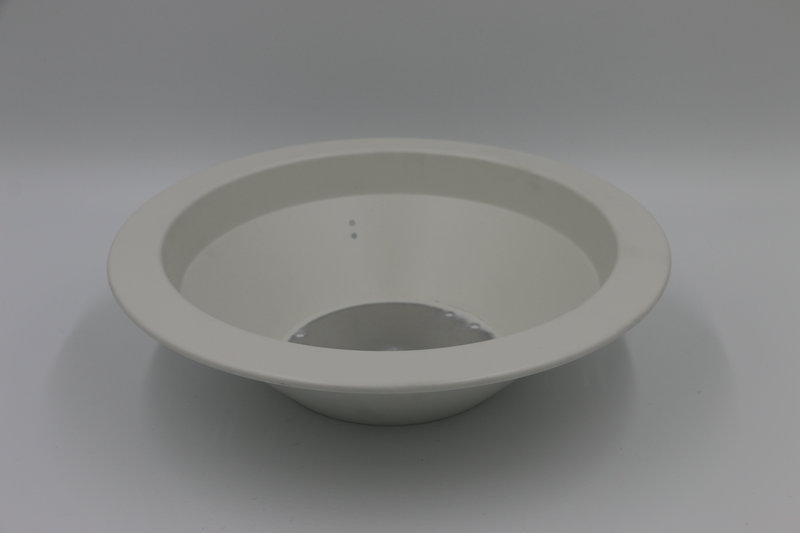

- All white downlight

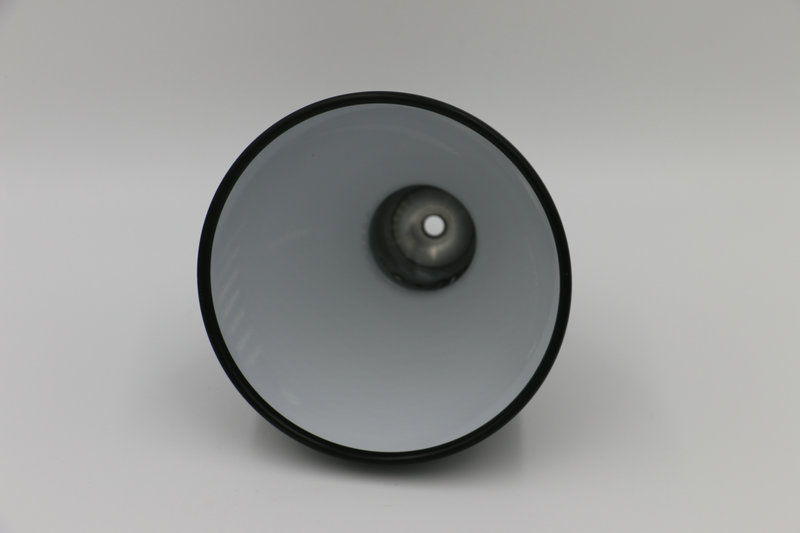

- Black and white lampshade

- Bright black hemisphere flower pot

- Car intake pipe

- Oil filter pocket

- Pure aluminum snare drum shell

- What are the requirements for the division of CNC machining processes?

- Water storage aluminum pan

- Wind impeller cover