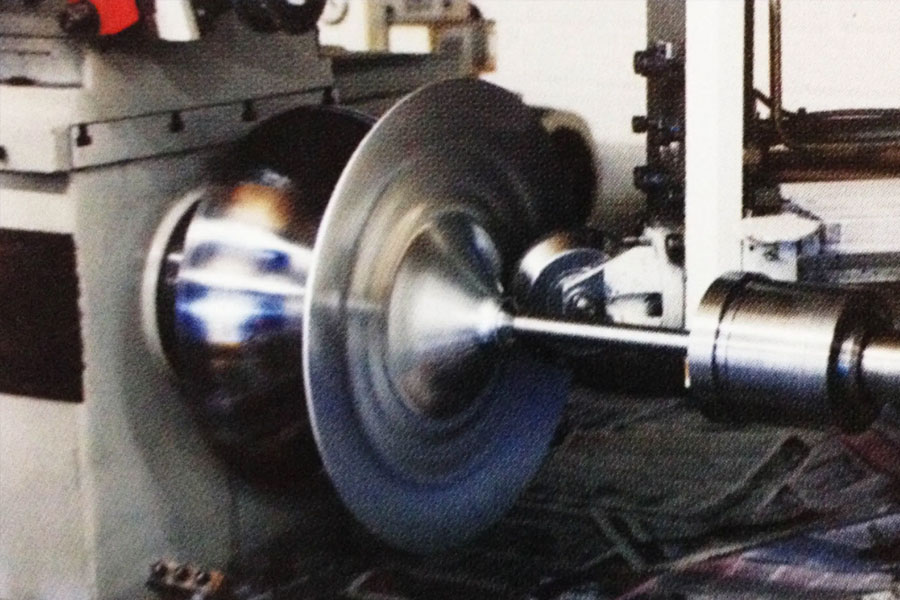

During spinning, the contact area between the runner and the blank is very small, the processing material has only local plastic deformation, and the deformation resistance is small. effective method. Spinning products have high precision, spinning equipment, good mechanical properties and a wide range of sizes. Spinning tools and molds are simple in structure and easy to replace; in terms of manufacturing certain product development, production management costs are lower than other research methods. The main disadvantage is that the production time is long, the output is low, and the variety is limited. It is suitable for the production of small batches and multi-variety products. The new traditional power spinning machine is hydraulically driven, equipped with hydraulic profiling and CNC systems.

Most of the small and medium-sized spinning machine tool enterprises use a horizontal type, and most of the large-scale spinning machine tools use a vertical type. Spinning machine tools require good rigidity, high power, high precision and good versatility. At present, large spinning machines can spin parts with a diameter of 6 meters, and the spinning wheel pressure can reach hundreds of tons.

The application of big data The application of big data is a dual challenge for furniture companies in technology and business. If they want to play the advantages of big data smoothly, furniture companies must be cautious.

Spinning processing enterprises must first have data, that is, spinning processing enterprises must get rid of the traditional development model, start to integrate into the modern Internet development state, and earnestly understand various data on raw materials, production, consumers, etc., and master a rich amount of data. It is the basis for realizing big data;

Large-scale CNC spinning enterprises must learn to combine data information with products and consumers, flanging and spinning equipment, and optimize products and services through big data analysis of product and consumer data.

Spinning utilizes metal ductility and combines the process characteristics of forging, extrusion, stretching, bending, ring rolling, cross rolling and rolling to achieve high-quality and efficient metal forming processes with little or no cutting.

Power spinning developed rapidly after the 1950s. This molding technology has the advantages of good deformation conditions, good product performance, small dimensional tolerance, high material utilization rate, wide product range, and the ability to process integral seamless hollow revolving parts.

NOTE: The location of the emergency stop push button switch should be very familiar, no need to look for it, the machine must be switched off before placing the fuse. Have enough working space to avoid danger. Water or oil can cause the ground to slip and cause danger. In order to prevent accidents, the working surface of metal spinning equipment should be kept clean and dry.

Danger: Do not touch control devices, transformers, motors, junction boxes, high-voltage terminals and other live parts with hands (or non-insulated items), otherwise it will cause electric shock. Do not touch the switch with wet hands, otherwise, it will also cause an electric shock.

Before using the switch, be sure, don’t make a mistake, don’t touch the switch. If a task requires more than two people to complete, then, in each operation step, we know that the CNC spinning machine is equipped with many safety devices to prevent injury and damage to operators and equipment.