In a quality inspection, the machine spinning plant determines whether the machined spinning parts manufactured meet the plant’s quality objectives. This mainly depends on whether the plane is uneven, whether the dimensional accuracy is appropriate, and whether it is suitable. In general, the repair rate is calculated based on the number of returned spun parts and the total monthly production. Many repaired machined spun parts are damaged or scratched during shipping due to improper packaging, which inadvertently increases manufacturing costs.

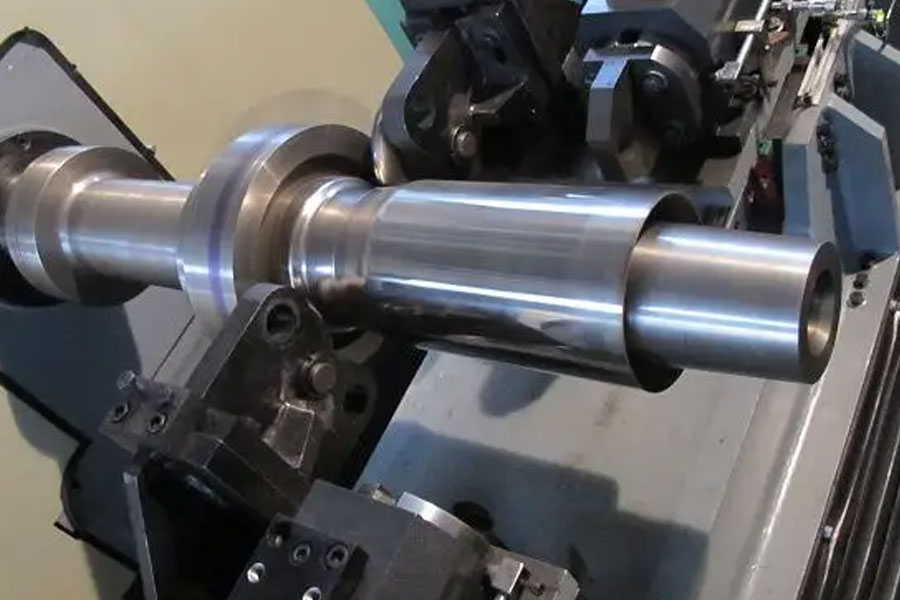

Stainless steel spinning

The study found that reasonable packaging of machined parts has a direct impact on the safety, quality, efficiency and cost of machined parts in the entire logistics process. Effective packaging management reduces manufacturing costs for manufacturers. Increased productivity plays an important role.

Therefore, in order to prevent the metal spinning parts from being damaged during transportation, it is necessary not only to effectively protect the processed spinning parts, but also to reduce the damage rate and repair rate, as well as handling and storage. In addition to meeting environmental protection requirements, choose not to pollute the environment as much as possible s material.