The metal spinning factory tells you that stamping parts processing is an important way to understand various processing methods, and what are the advantages of stamping parts processing has also…

Stamping parts processing is a very important way

The metal spinning factory tells you that stamping parts processing is an important way to understand various processing methods, and what are the advantages of stamping parts processing has also…

At present, the general trend of foreign metal spinning is to develop in the direction of scale, serialization, high precision, multi-function and automation. 1. Develop in the direction of large-scale…

Many customers consider buying a metal spinning machine, but they don't know much about the spinning machine and don't know how to evaluate whether the spinning machine is suitable for…

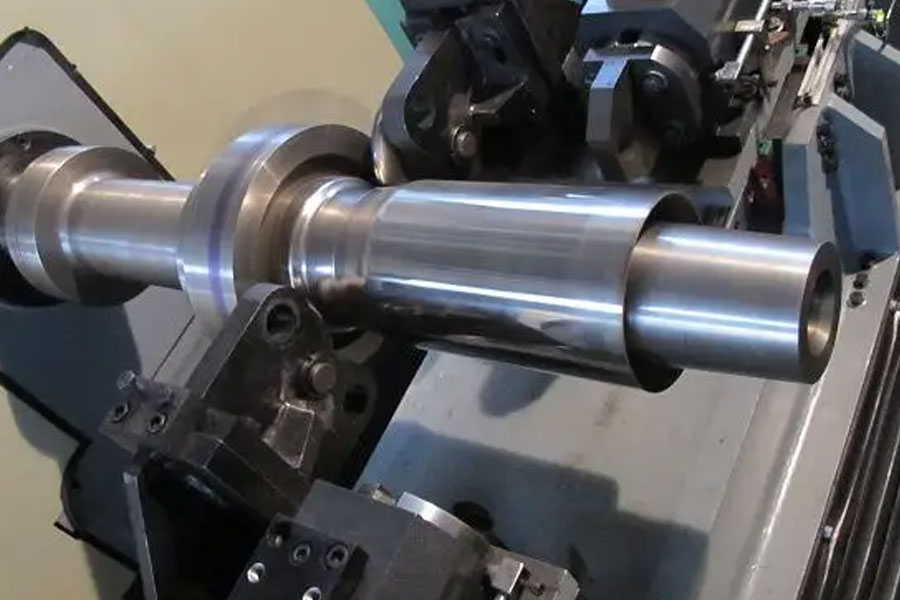

Spinning is a method by which flat blanks or preforms can be processed to obtain thin-walled hollow rotating articles. In the field of metal processing engineering, spinning is a new…

Metal spinning can be seen everywhere in our daily life. Metal spinning parts manufacturers are aware of the huge potential of the metal spinning parts market, and continue to increase…

The general production process of metal spinning technology is the same, so what is the price difference between CNC spinning and metal spinning? The so-called metal spinning is to fix…

Service performance is a key factor to consider when selecting materials to manufacture spinning machined parts. Different machined parts require different properties. When selecting a material, the first task is…

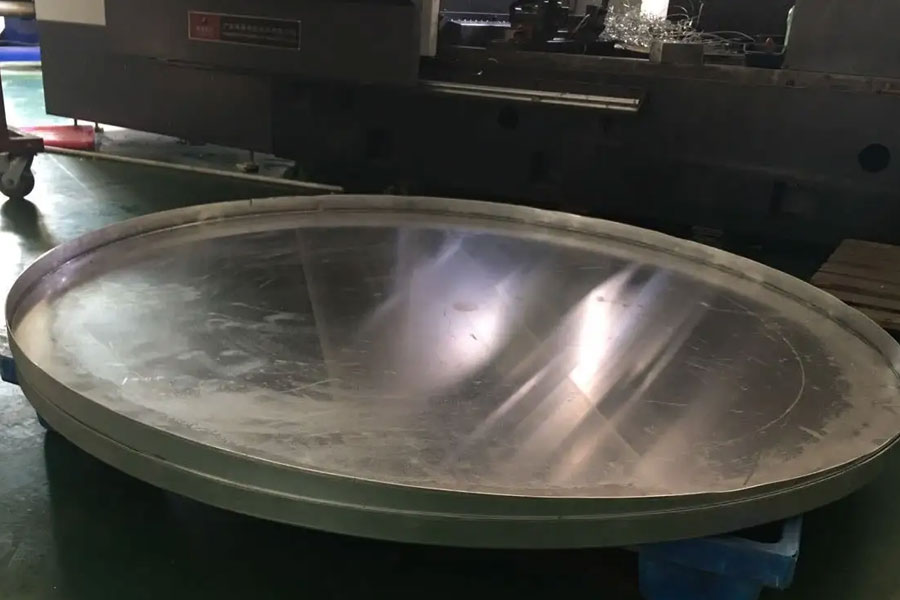

In a quality inspection, the machine spinning plant determines whether the machined spinning parts manufactured meet the plant's quality objectives. This mainly depends on whether the plane is uneven, whether…

CNC spinning usually requires die spinning. Once the product is formed, the spun product adheres to the mold. It can be difficult to remove the product from the mold, which…

If the strength and stiffness required by the design are met, the machining process should be considered separately, and the economy and rationality of cnc machining and spinning should be…