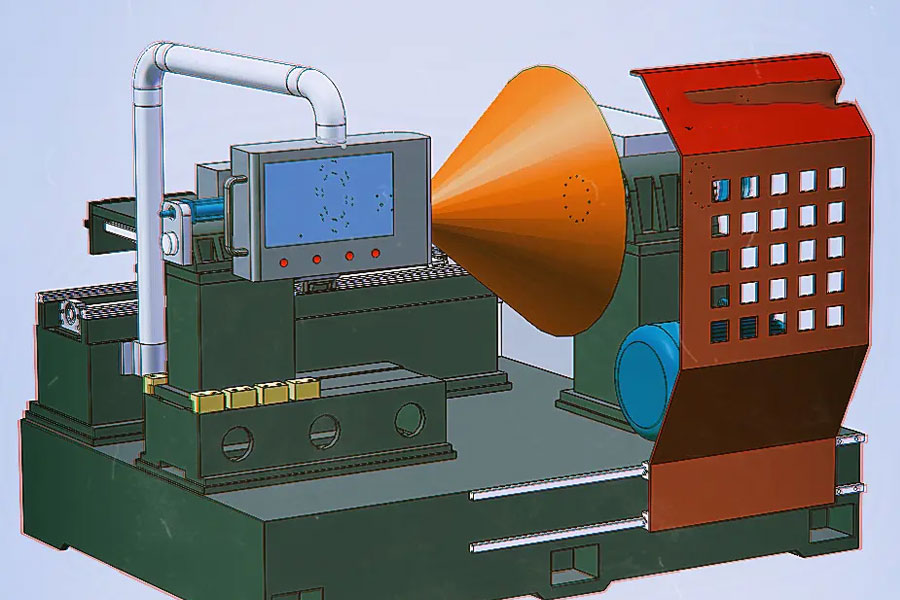

The so-called metal spinning processing method is to fix the blank of the metal structural material on the spinning die, put pressure on it and carry out deep processing of the product. The spinning machine here is the same as the ordinary machine tool. Due to the existence of metal materials in the processing process, it will definitely be different from ordinary materials in terms of pressure.

With the continuous development of society, science and technology have also developed. In recent years, CNC spinning technology has been widely used in industry.

The ordinary processing technology in the past has not been able to meet the needs of the market. People continue to study and finally find that CNC lathes save time and energy.

What social stability do the CNC spinning enterprises in our market generally rely on? Since CNC lathes require program control, ordinary operators generally have no consideration for complex programs.

Here, it is necessary to specify the different pressure conditions required for each place according to the shape and size of the product. The hardness of the metal can be very different from that of the general material, in which case the dies that may need to be spun may be different.

The material of the spinning die is different according to its pressure, and its market price is also different, which leads to a big difference between the processing price of metal spinning and the processing price of general materials on the spinning die.

Therefore, there must be a certain gap in the overall processing cost. Therefore, differences in materials can lead to large differences in processing prices.